Reverse Engineering

Design & Engineering

Mechanical Design

Rapid Prototyping

Reverse Engineering

FEM Simulation

Quality and Validation

Quality System Support

VMP - DQ IQ OQ PQ Validation

Standard Operative Procedures (SOP) (IOP)

Technical File / Design Dossier

Design Control

DHF Design History File

Risk Management Process

Clinical Evaluation

Testing

Mechanical Testing

Analysis on Plastics

Biological Safety Evaluation

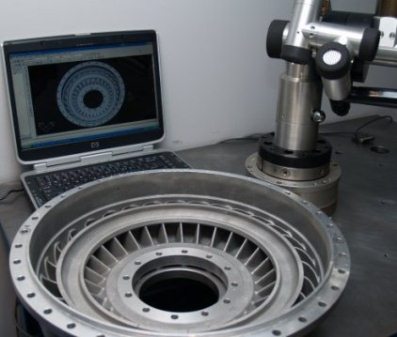

Starting from a prototype, or from an object that you want to reconstruct, or from specific parts of which you want to perform particular analysis, through the process of reverse engineering its CAD model is obtained. This is used to easily carry out the modification of existing parts, the development of new parts, the dimensional analysis and begin the manufacturing process.

Meaning and purpose of reengineering reverse:

- digitization of the surface

- editing and filtering of measured data

- segmentation and creation of mathematical models

- creation of CAD models